Advanced Mechanical Recycling

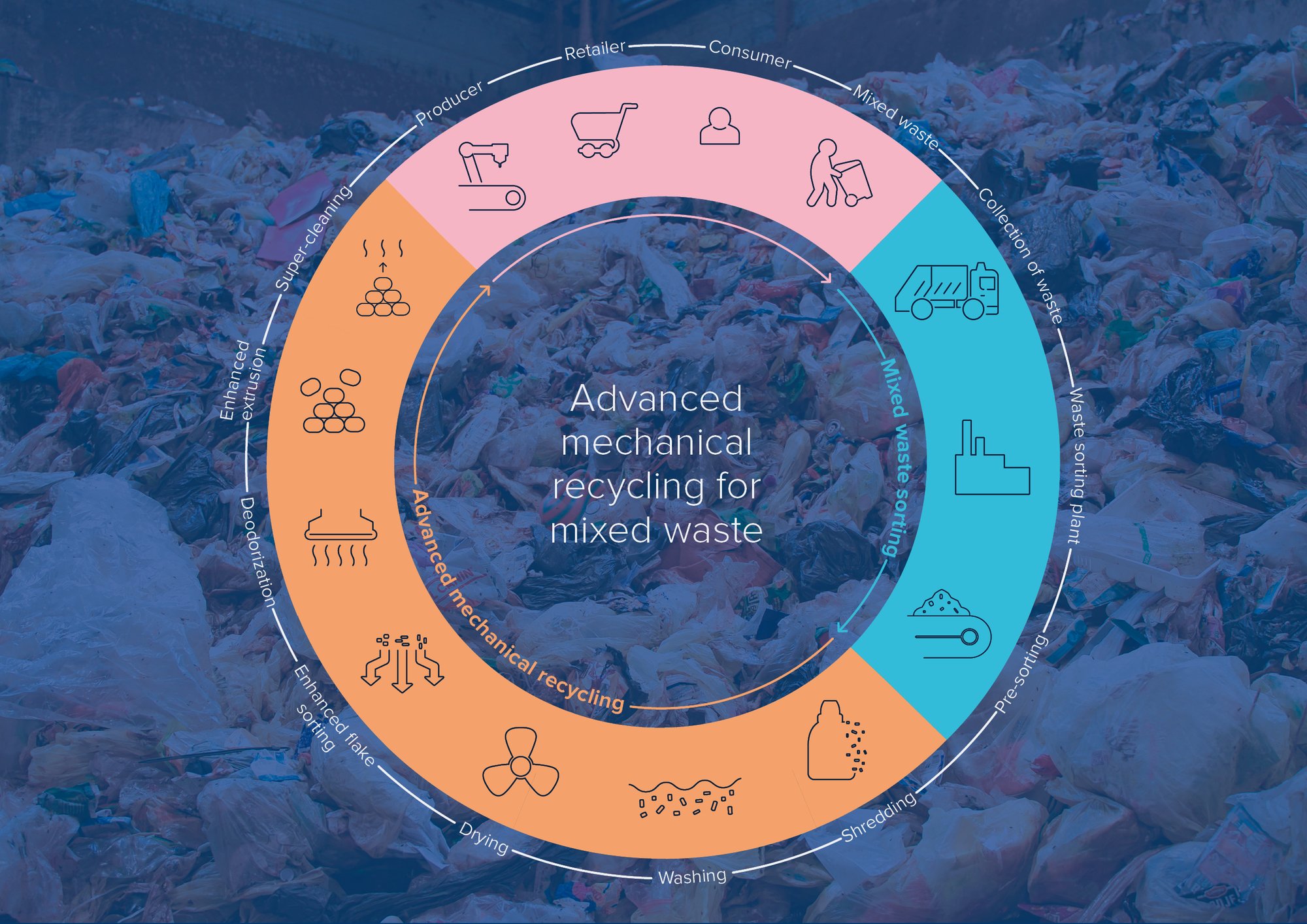

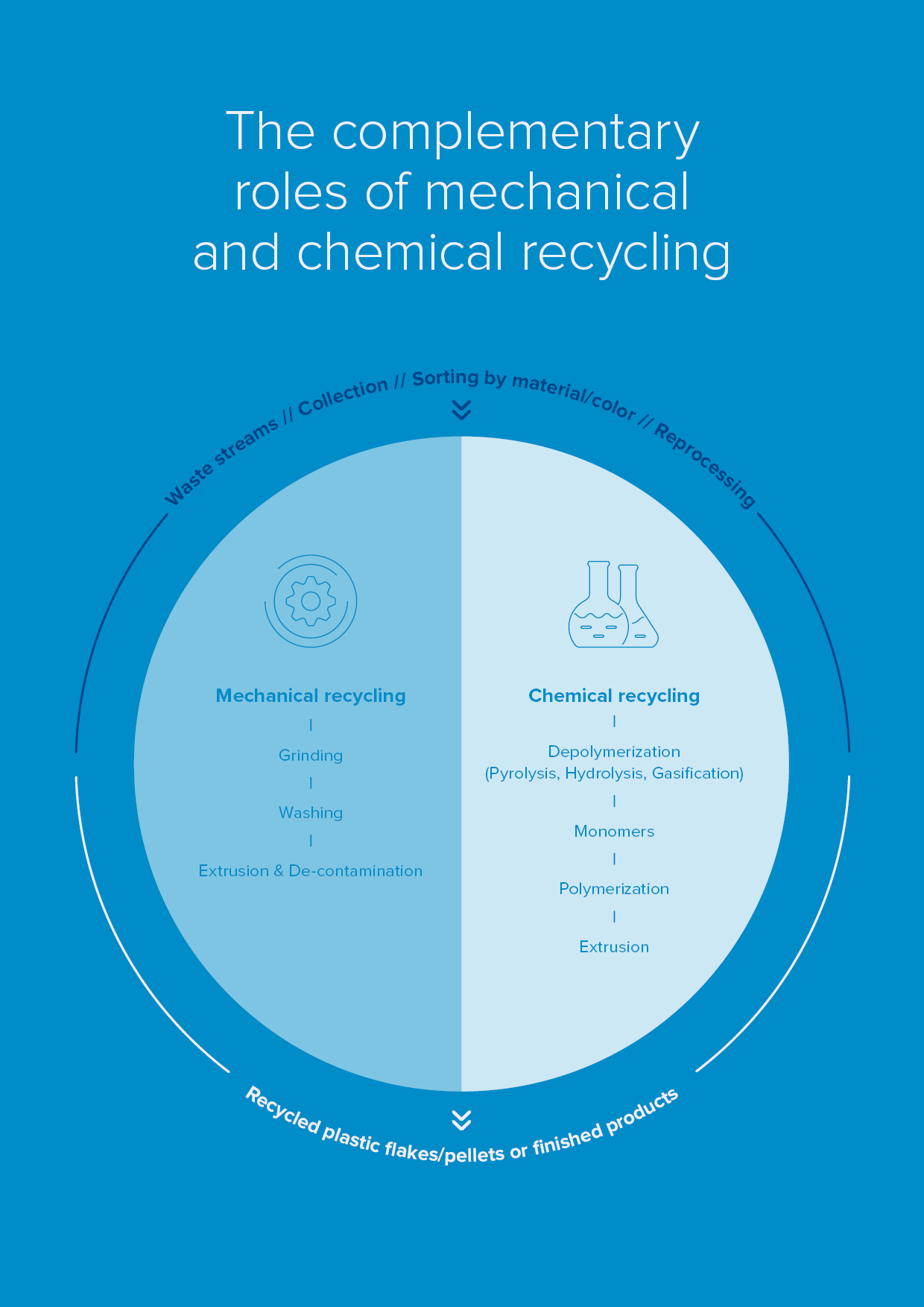

Advanced mechanical recycling (AMR) has been upgraded to enable the transformation of post-consumer plastic from different material streams (including mixed waste) into high-quality, ready-for-market recycled plastic content.

How does advanced mechanical recycling work?

Advanced mechanical recycling is a revolutionary new technique that transforms household plastic waste into high-quality recycled plastic content.

Advanced Mechanical Recycling (AMR) has been used to achieve closed-loop (bottle-to-bottle) recycling for PET beverage containers. Today, the AMR process has been upgraded to help achieve circularity for plastic beyond PET beverage containers.

With these upgrades, it is now possible to create virgin-like recycled plastic pellets from source-separated waste streams and mixed waste streams – ensuring that the highest quality recyclate is available to those industries that depend on superior feedstock quality to reduce their C02 emissions and reach recycling and recycled content targets.

TOMRA Talks Circular

Listen to industry experts on our podcast, which aims to affect real change with real conversations.

The supply and demand challenge

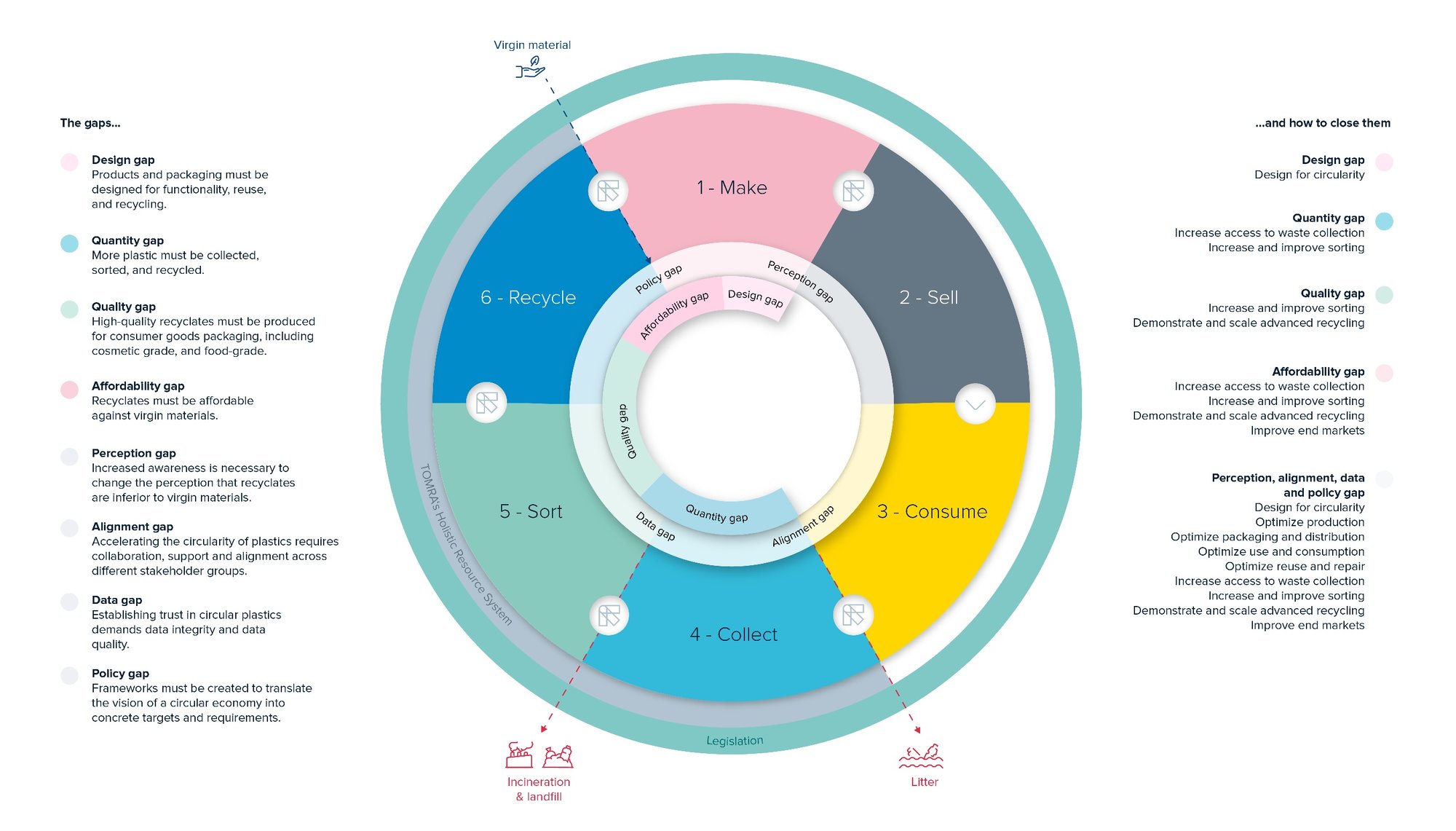

The need to drastically expand the amount of plastic that is recovered is increasing as consumer demand grows, recycling and recycled content targets become more widespread, and the financial implications of using primary raw materials become more stringent. As it stands, there isn’t enough high-quality feedstock to meet this growing demand. Upgrades to the advanced mechanical recycling (AMR) process can solve this supply and demand challenge by:

1. Closing the quality gap. With the latest technology, and the addition of new and enhanced steps to the traditional mechanical recycling process, AMR can produce high-quality recyclate from not only source separated waste, but from mixed waste streams as well.

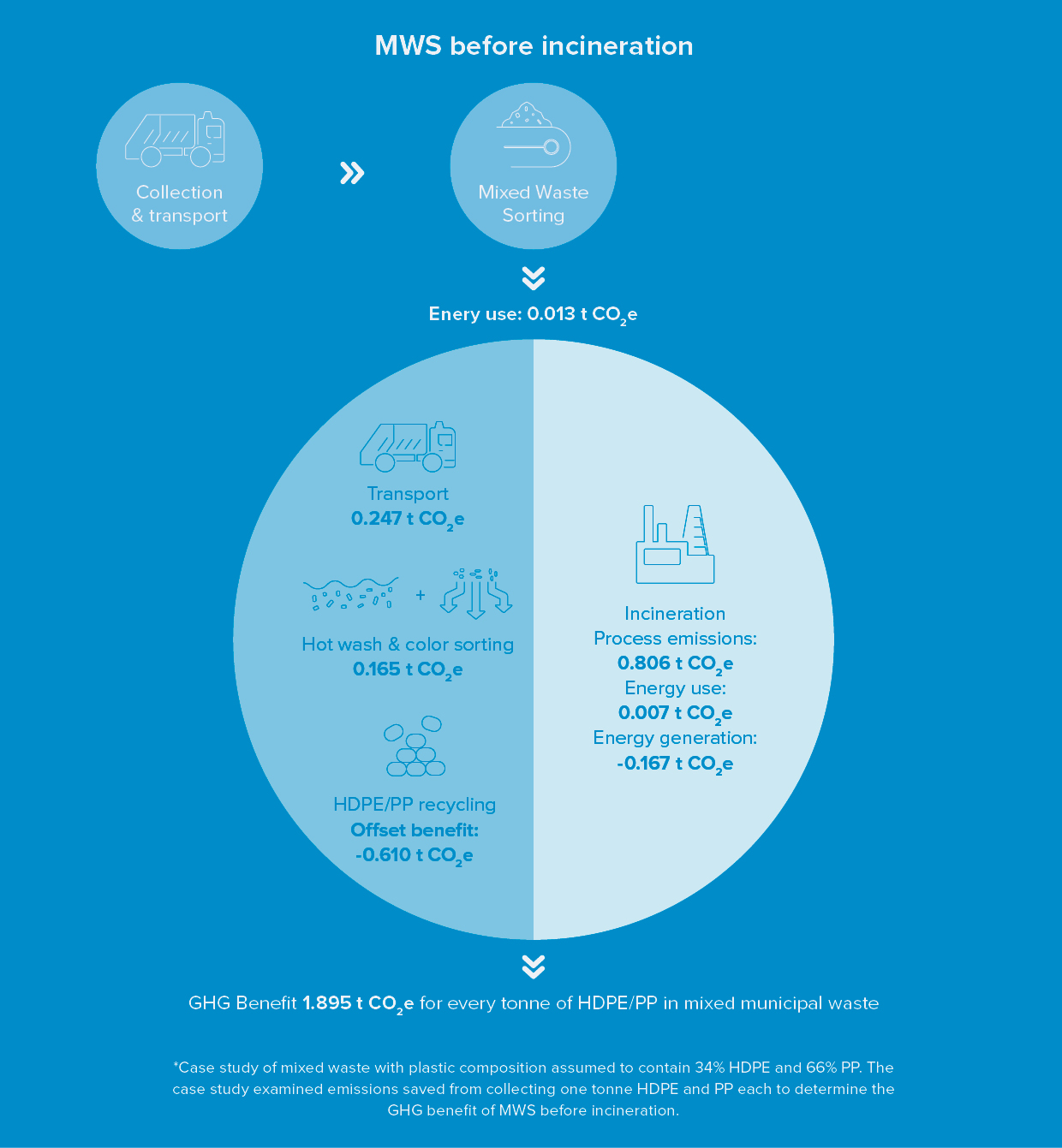

2. Closing the quantity gap. Rescuing a large amount of waste that would otherwise end up in landfills or incinerators and processing it into virgin-like recyclate is imperative to producing sufficient amounts of recycled content. Mixed waste sorting (MWS) can achieve this.

When AMR is coupled with MWS, it is possible to fill the ever-growing demand for high-quality recyclates. To achieve true resource circularity, these solutions must be implemented at scale, therefore, investment in infrastructure is vital.

Closing the quality and quantity gaps

Today, only 2% of plastic packaging is recycled in closed-loop systems. By 2030, TOMRA aims to enable the collection of 40% of post-consumer plastic packaging, and the closed-loop recycling of 30% of all post-consumer plastic packaging. To achieve these ambitious commitments, the quality and quantity gaps across the value chain must be closed.

.png?width=3000&height=2000&name=MicrosoftTeams-image%20(50).png)

AMR Infographics

View infographics explaining AMR visually below.

TOMRA’s webcast: Advanced mechanical recycling: Enabling true circularity for plastics, now

Watch two industry experts discuss how we can close existing quality and quantity gaps along the plastics value chain by producing enough virgin-like recyclate from different material streams – including mixed waste streams – with advanced mechanical recycling.

.png?width=788&height=200&name=tomra_lockup_h_1cw_png%20(1).png)

.png?width=281&name=MicrosoftTeams-image%20(47).png)